When used with a run capacitor a 15 000 ohm to 18 000 ohm 2 w bleed resistor should be attached to the start capacitor to prevent possible arcing when the relay contacts open.

Potential relay troubleshooting.

Potential relay operation and testing.

Replacement relays can be cross referenced for different manufacturers using convenient tables via the internet.

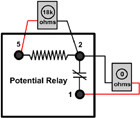

After taking all of the connecting wires off of the potential relay measure the resistance across the 1 and 2 terminals.

Knowing the sequence of operation for this type of starting relay can help you diagnose confirm or rule out certain service problems.

This video explains the terminal arrangement of a potential relay how to wire it up and how it works.

All you have to do is touch the ends of the.

It s probably a bad potential relay.

Remember short out the start cap used above.

I ve used this procedure many times.

A simple ohmmeter is all that is needed to troubleshoot a potential relay.

My paperback and e book.

Potential starting relays consist of a high resistance coil and a set of normally closed contacts.

Troubleshooting of a potential relay can be done with an ohmmeter.

A simple ohmmeter is all that is needed to troubleshoot a potential relay.

The resistance should read close to zero since there are normally closed contacts between terminals 1 and 2.

The coil is wired between terminals 2 and 5 with the contacts between terminals 1 and 2.

The above procedure simply mimics the action of the potential relay.

I show the.

Whenever possible the model number on the old relay should be used when ordering a new relay.